Client Objectives

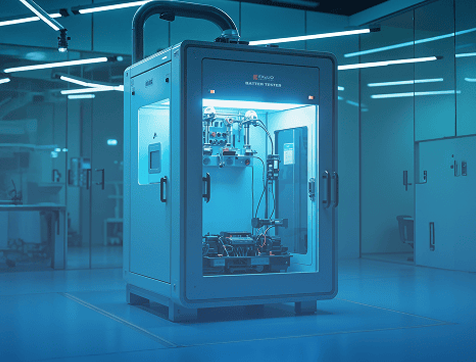

The client, a leading manufacturer of electric vehicle (EV) chargers, aimed to enhance the performance and reliability of their charging stations. They sought a comprehensive testing solution that could:

- Ensure compliance with international safety and performance standards.

- Reduce downtime and maintenance costs by identifying potential failures early.

- Improve customer satisfaction by guaranteeing that charger’s function optimally under various conditions.

Key Features

- The EV charger testing solution implemented by Exeliq Tech Solutions included:

- Programmable AC source up to 20 KVA for variable test conditions.

- Multichannel power meter for input/output characteristics with advanced THD measurements.

- Thermal and humidity chambers for testing in realistic environmental conditions.

- Inbuilt CAN support for data packet verification & calibration.

- Includes HV/IR and withstand voltage tests.

The Results

The implementation of the EV charger testing solution led to significant improvements:

- Performance Improvement: The client reported a 30% increase in charger reliability, with fewer instances of failure during peak usage times.

- Cost Savings: Maintenance costs were reduced by 25%, as early detection of issues allowed for proactive repairs.

- Faster Time to Market: Streamlined testing processes enabled quicker product development cycles, reducing time-to-market by 15%.

- Enhanced Customer Satisfaction: Customer feedback indicated a 40% increase in satisfaction ratings due to improved charger performance and reliability.

Client Testimony

"The testing solution provided by Exeliq Tech Solutions has transformed our approach to quality assurance. The ability to perform comprehensive tests and receive real-time data has not only improved our product reliability but also boosted our team's efficiency.

Key Takeaways

- Implementing a robust testing solution is crucial for maintaining high-quality standards in the EV charger manufacturing process.

- Automated and real-time testing processes can significantly enhance operational efficiency and reduce costs.

- Compliance with international safety standards is essential for market success and customer trust.

- Proactive issue identification leads to better product reliability, increased customer satisfaction, and improved financial performance.

More Case Studies

EV Motor Testing Solution Boosts Efficiency and Reliability

Learn More

Automated EV Controller Testing Enhances Efficiency

Learn More

How Our EOL Testing ATE is Safeguarding the Future

Learn More

Automated EV Cluster Testing Enhances Efficiency

Learn More