Client Objectives

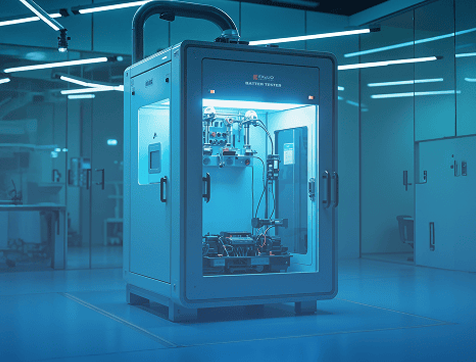

The client, a prominent electric vehicle manufacturer, sought a reliable and efficient testing solution for their new line of high-capacity EV batteries. Their primary objectives included:

- Ensuring battery safety and performance under various environmental conditions.

- Reducing the time and cost of the testing process.

- Providing accurate diagnostics to minimize the risk of battery failure.

- Complying with industry regulations and standards for battery testing.

Key Features of the Solution

- Automated Testing Capabilities: Enabled seamless and repeatable testing cycles, reducing manual intervention and improving testing precision.

- Comprehensive Diagnostic Tools: Equipped with advanced tools for evaluating thermal behavior, charge-discharge cycles, and degradation patterns in real-time.

- Environmental Simulation: Offered high-fidelity simulations of various real-world conditions, including extreme temperatures, humidity, and rapid acceleration, to ensure battery durability.

- Data Analysis and Reporting: Integrated analytics for monitoring battery performance, allowing for proactive adjustments and quick identification of potential failure points.

- Compliance with Global Standards: Aligned with international standards such as IEC and SAE for EV battery testing, ensuring the client's global market readiness.

The Results

- Improved Battery Reliability: The client observed a 25% reduction in battery failure rates due to the advanced diagnostic insights provided by the solution.

- Time Efficiency: Testing duration was reduced by 30%, allowing the client to expedite product releases without compromising on quality.

- Cost Savings: Automation and efficient diagnostics decreased overall testing costs by 20%, saving significant resources over multiple product cycles.

- Enhanced Safety Standards: The testing solution helped the client identify and mitigate safety risks early, resulting in a safer final product.

Client Testimony

"The EV battery testing solution transformed our approach to quality control and product safety. Its precision and efficiency not only accelerated our testing processes but also assured us of our batteries' robustness across various conditions.

Key Takeaways

- Automated testing and comprehensive diagnostics significantly enhance battery reliability and reduce failure rates.

- Real-time data analysis allows for proactive interventions, reducing potential safety risks.

- A robust battery testing solution aligns with global standards, ensuring compliance for international market entry.

- Time and cost efficiencies in testing contribute to faster product launches and improved ROI for EV manufacturers.

More Case Studies

EV Motor Testing Solution Boosts Efficiency and Reliability

Learn More

Automated EV Controller Testing Enhances Efficiency

Learn More

How Our EOL Testing ATE is Safeguarding the Future

Learn More

Automated EV Cluster Testing Enhances Efficiency

Learn More